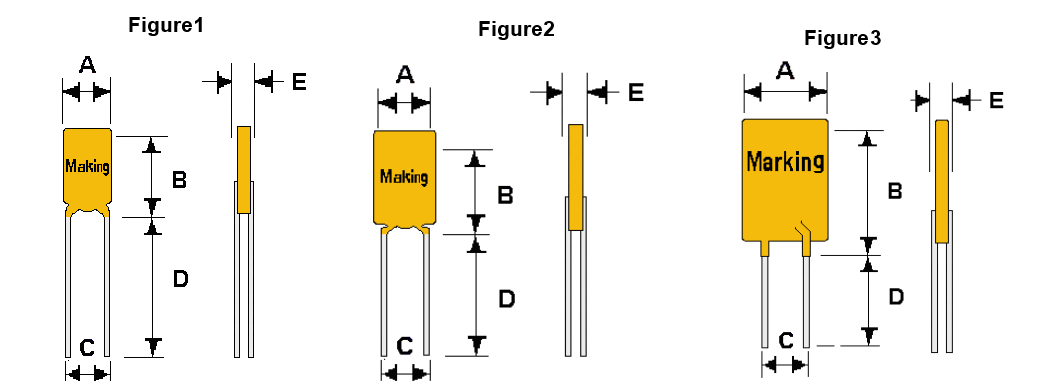

| Part No | Figure / Lead Option |

lhold (A) | Itrip (A) |

Vmax (V) |

Imax (A) |

Pd typ (W) |

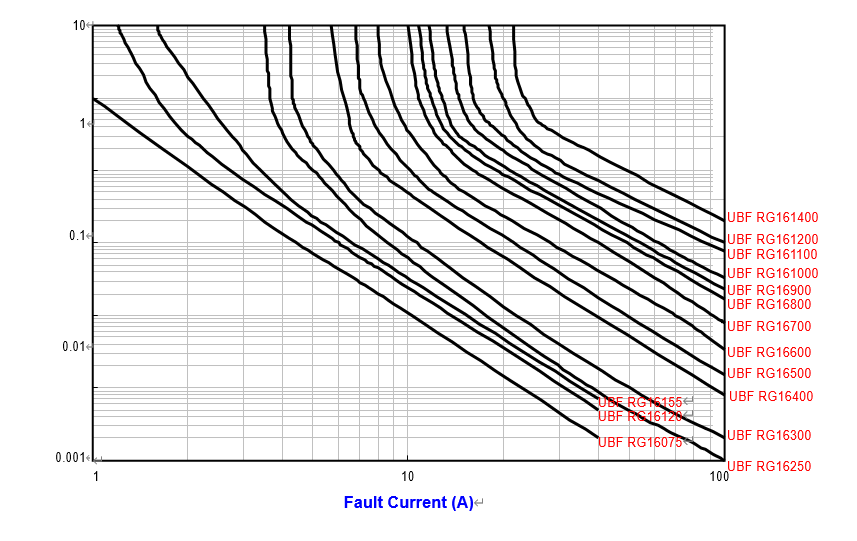

Max. (A) |

Time-to-trip (s) |

R min (Ω) |

R1 Max (Ω) |

|

| UBF | RG16075 | Fig. 1, Ø0.51, Sn/CuFe | 0.75 | 1.30 | 16 | 40 | 0.3 | 8.0 | 0.4 | 0.080 | 0.023 |

| UBF | RG16120 | Fig. 1, Ø0.51, Sn/CuFe | 1.20 | 2.00 | 16 | 40 | 0.6 | 8.0 | 0.5 | 0.040 | 0.014 |

| UBF | RG16155 | Fig. 1, Ø0.51, Sn/CuFe | 1.55 | 2.70 | 16 | 40 | 0.7 | 8.0 | 0.6 | 0.030 | 0.012 |

| UBF | RG16250 | Fig. 1, Ø0.51, Sn/CuFe | 2.50 | 4.70 | 16 | 100 | 1.0 | 12.5 | 5.0 | 0.022 | 0.053 |

| UBF | RG16300 | Fig. 2, Ø0.81, Sn/CuFe | 3.00 | 5.10 | 16 | 100 | 2.3 | 15.0 | 2.0 | 0.034 | 0.105 |

| UBF | RG16400 | Fig. 2, Ø0.81, Sn/CuFe | 4.00 | 6.80 | 16 | 100 | 2.4 | 20.0 | 3.5 | 0.020 | 0.063 |

| UBF | RG16500 | Fig. 2, Ø0.81, Sn/CuFe | 5.00 | 8.50 | 16 | 100 | 2.6 | 25.0 | 3.6 | 0.014 | 0.044 |

| UBF | RG16600 | Fig. 2, Ø0.81, Sn/CuFe | 6.00 | 10.20 | 16 | 100 | 2.8 | 30.0 | 5.8 | 0.009 | 0.033 |

| UBF | RG16700 | Fig. 2, Ø0.81, Sn/CuFe | 7.00 | 11.90 | 16 | 100 | 3.0 | 35.0 | 8.0 | 0.006 | 0.021 |

| UBF | RG16800 | Fig. 2, Ø0.81, Sn/CuFe | 8.00 | 13.60 | 16 | 100 | 3.0 | 40.0 | 9.0 | 0.005 | 0.018 |

| UBF | RG16900 | Fig. 2, Ø0.81, Sn/CuFe | 9.00 | 15.30 | 16 | 100 | 3.3 | 45.0 | 12.0 | 0.004 | 0.015 |

| UBF | RG161000 | Fig. 2, Ø0.81, Sn/CuFe | 10.00 | 17.00 | 16 | 100 | 3.6 | 50.0 | 12.5 | 0.003 | 0.012 |

| UBF | RG161100 | Fig. 2, Ø0.81, Sn/CuFe | 11.00 | 18.70 | 16 | 100 | 3.7 | 55.0 | 13.5 | 0.003 | 0.010 |

| UBF | RG161200 | Fig. 2, Ø0.81, Sn/CuFe | 12.00 | 20.40 | 16 | 100 | 4.2 | 60.0 | 16.0 | 0.002 | 0.009 |

| UBF | RG161400 | Fig. 2, Ø0.81, Sn/CuFe | 14.00 | 23.80 | 16 | 100 | 4.6 | 70.0 | 20.0 | 0.002 | 0.008 |

| Ihold | Hold current is the maximum current that UB Fuse can pass through without interruption at 20°C unless otherwise specified. |

| Itrip | Trip current is the minimum current that will switch the device from low resistance state to high resistance state at 20°C unless specified. |

| Vmax | The maximum voltage device can withstand without damage at rated current. |

| Imax | The maximum current device can withstand without damage at rated voltage. |

| Pd | The power dissipated from device when in the tripped state at 20°C unless otherwise specified. |

| R min | The minimum resistance of device as received from the factory at 20°C unless otherwise specified. |

| R max | The maximum resistance of device as received from the factory at 20°C unless otherwise specified. |

| R1max | The maximum resistance of device when measured one hour post trip at 20°C unless otherwise specified. |

| Max. Time-to-trip |

The maximum time for device to trip at specified current ratings at 20°C unless otherwise specified. |

| Test | Test Conditions | Resistance Change |

| Passive Aging | +85°C, 1000 hours | ±5% typical resistance change |

| Humidity Aging | +85°C, 85% R.H., 7 days | ±5% typical resistance change |

| Thermal Shock | +85°C to -40°C, 10 times MIL-STD-202, Method 107G |

±5% typical resistance change |

| Vibration | MIL-STD-883C, Condition A | No change |

| Solvent resistance | MIL-STD-202, Method 215 | No change |

| A | B | C | D | E | F | |

| Part No | Max. | Max. | Typical | Min. | Max. | Typical |

| UBF RG16075 | 6.9 | 11.4 | 5.1 | 7.6 | 3.0 | 0.8 |

| UBF RG16120 | 6.9 | 11.7 | 5.1 | 7.6 | 3.0 | 0.8 |

| UBF RG16155 | 6.9 | 11.7 | 5.1 | 7.6 | 3.0 | 0.8 |

| UBF RG16250 | 8.9 | 12.8 | 5.1 | 7.6 | 3.0 | 1.2 |

| UBF RG16300 | 7.1 | 11.0 | 5.1 | 7.6 | 3.0 | 1.2 |

| UBF RG16400 | 8.9 | 12.8 | 5.1 | 7.6 | 3.0 | 1.2 |

| UBF RG16500 | 10.4 | 14.3 | 5.1 | 7.6 | 3.0 | 1.2 |

| UBF RG16600 | 10.7 | 17.1 | 5.1 | 7.6 | 3.0 | 1.2 |

| UBF RG16700 | 11.2 | 19.7 | 5.1 | 7.6 | 3.0 | 1.2 |

| UBF RG16800 | 12.7 | 20.9 | 5.1 | 7.6 | 3.0 | 1.2 |

| UBF RG16900 | 14.0 | 21.7 | 5.1 | 7.6 | 3.0 | 1.2 |

| UBF RG161000 | 16.5 | 24.1 | 5.1 | 7.6 | 3.0 | 1.2 |

| UBF RG161100 | 17.5 | 26.0 | 5.1 | 7.6 | 3.0 | 1.2 |

| UBF RG161200 | 17.5 | 28.0 | 10.2 | 7.6 | 3.0 | 1.4 |

| UBF RG161400 | 27.9 | 27.9 | 10.2 | 7.6 | 3.0 | 1.4 |

| UL File Number | E 119550 |

| c-UL File Number | E 119550 |

| TUV File Number | Pending |

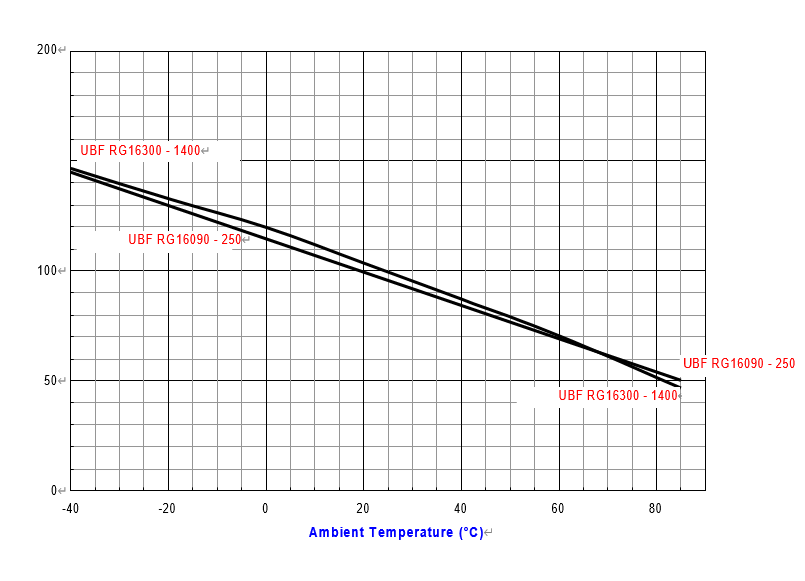

| Part No | -40 | -20 | 0 | 20 | 40 | 60 | 85 |

| UBF RG16075 | 1.10 | 0.98 | 0.86 | 0.75 | 0.62 | 0.50 | 0.39 |

| UBF RG16120 | 1.75 | 1.56 | 1.38 | 1.20 | 1.00 | 0.80 | 0.62 |

| UBF RG16155 | 2.26 | 2.02 | 1.78 | 1.55 | 1.29 | 1.04 | 0.81 |

| UBF RG16250 | 3.73 | 3.30 | 3.00 | 2.50 | 2.20 | 1.78 | 1.18 |

| UBF RG16300 | 4.47 | 3.96 | 3.60 | 3.00 | 2.64 | 2.13 | 1.41 |

| UBF RG16400 | 5.96 | 5.28 | 4.80 | 4.00 | 3.52 | 2.84 | 1.88 |

| UBF RG16500 | 7.45 | 6.60 | 6.00 | 5.00 | 4.40 | 3.55 | 2.35 |

| UBF RG16600 | 8.94 | 7.92 | 7.20 | 6.00 | 5.28 | 4.26 | 2.82 |

| UBF RG16700 | 10.43 | 9.24 | 8.40 | 7.00 | 6.16 | 4.79 | 3.29 |

| UBF RG16800 | 11.92 | 10.56 | 9.60 | 8.00 | 7.04 | 5.68 | 3.76 |

| UBF RG16900 | 13.41 | 11.88 | 10.80 | 9.00 | 7.92 | 6.39 | 4.23 |

| UBF RG161000 | 14.90 | 13.20 | 12.00 | 10.00 | 8.80 | 7.10 | 4.70 |

| UBF RG161100 | 16.39 | 14.52 | 13.20 | 11.00 | 9.68 | 7.81 | 5.17 |

| UBF RG161200 | 17.88 | 15.84 | 14.40 | 12.00 | 10.56 | 8.52 | 5.64 |

| UBF RG161400 | 20.86 | 18.48 | 16.80 | 14.00 | 12.32 | 9.94 | 6.58 |

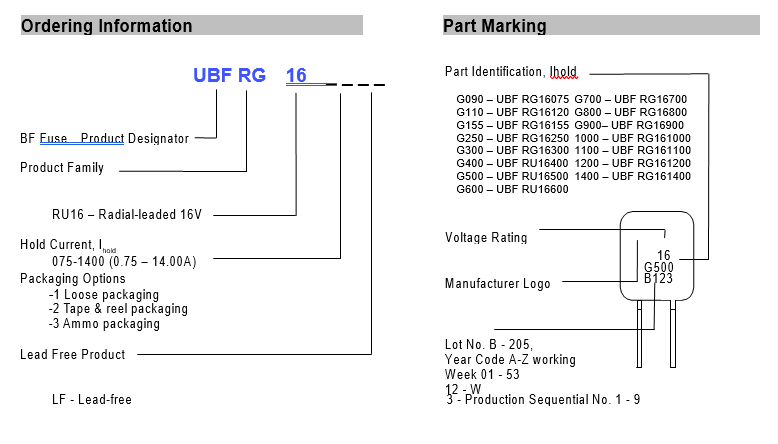

| Part No | -1 Loose Pack Quantity | -2 Tape & Reel Quantity | -3 Ammo Pack Quantity |

| UBF RG16075 | 500 | 3000 | 2000 |

| UBF RG16120 | 500 | 3000 | 2000 |

| UBF RG16155 | 500 | 3000 | 2000 |

| UBF RG16250 | 500 | 3000 | 2000 |

| UBF RG16300 | 500 | 2500 | 2000 |

| UBF RG16400 | 500 | 2500 | 2000 |

| UBF RG16500 | 500 | 2000 | 2000 |

| UBF RG16600 | 500 | 2000 | 2000 |

| UBF RG16700 | 500 | 1500 | 1500 |

| UBF RG16800 | 500 | 1000 | 1000 |

| UBF RG16900 | 500 | 1000 | 1000 |

| UBF RG161000 | 250 | 1000 | 1000 |

| UBF RG161100 | 250 | 1000 | 1000 |

| UBF RG161200 | 250 | 1000 | 1000 |

| UBF RG161400 | 250 | 1000 | 1000 |

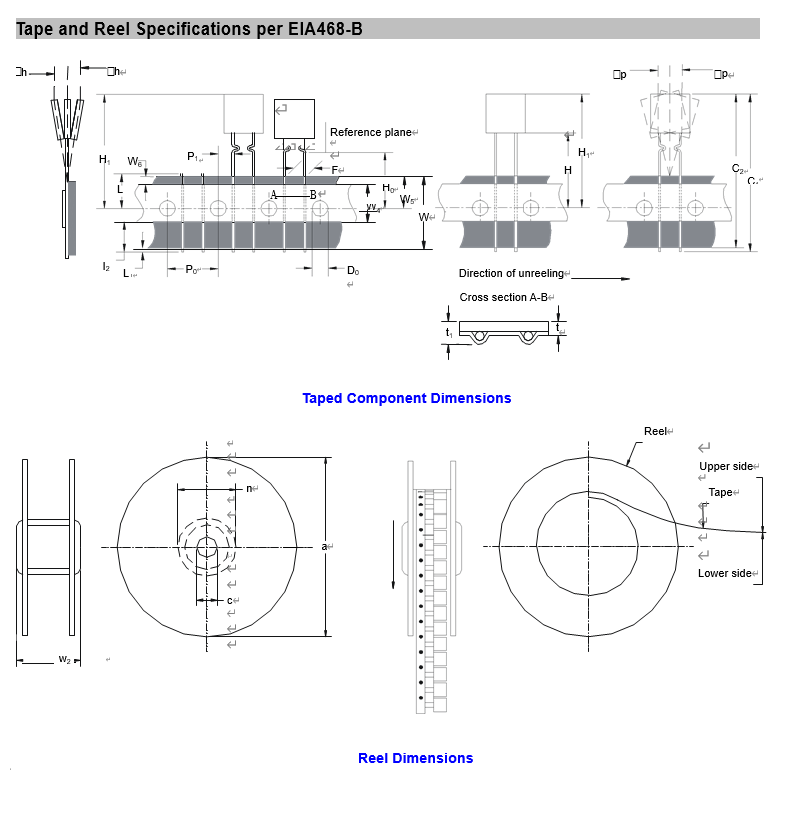

| Description | EIA Mark |

Dimension | Tolerance |

| Carrier tape width | W | 18 | -0.5/+1.0 |

| Hold-down tape width | W4 | 11 | Minimum |

| Top distance between tape edges | W6 | 3 | Maximum |

| Sprocket hole position | W5 | 9 | -0.5/+0.75 |

| Sprocket hole diameter | D0 | 4 | ±0.2 |

| Abscissa to plane (kinked lead) UBF RG16075 - 250 | H0 | 16.0 | ±0.5 |

| Abscissa to plane (straight lead) UBF RG16300 - 1400 | H | 18.5 | ±2.5 |

| Abscissa to top UBF RG16090 - 600 | H1 | 32.2 | Maximum |

| Abscissa to top UBF RG16700 - 1400 | H1 | 47.5 | Maximum |

| Overall width w/lead protrusion UBF RG16075 - 600 | C1 | 43.2 | Maximum |

| Overall width w/lead protrusion UBF RG16700 - 1400 | C1 | 58 | Maximum |

| Overall width w/o lead protrusion UBF RG16090 - 600 | C2 | 42.5 | Maximum |

| Overall width w/o lead protrusion UBF RG16700 - 1400 | C2 | 57 | Maximum |

| Lead protrusion | L1 | 1.0 | Maximum |

| Protrusion of cut-out | L | 11.0 | Maximum |

| Protrusion beyond hold-down tape | I2 | Not specified | -- |

| Sprocket hole pitch | P0 | 12.7 | ±0.3 |

| Device pitch UBF RG16090 - 700 | -- | 12.7 | ±0.3 |

| Device pitch UBF RG16800 - 1400 | -- | 25.4 | ±0.6 |

| Pitch tolerance | -- | 20 consecutive | ±1 |

| Tape thickness | t | 0.9 | Maximum |

| Overall tape and lead thickness UBF RG16075 - 250 | t1 | 1.5 | Maximum |

| Overall tape and lead thickness UBF RG16300 - 1100 | t1 | 2.0 | Maximum |

| Overall tape and lead thickness UBF RG161200 - 1400 | t1 | 2.3 | Maximum |

| Splice sprocket hole alignment | -- | 0 | ±0.3 |

| Body lateral deviation | △h | 0 | ±1.0 |

| Body tape plane deviation | △p | 0 | ±1.3 |

| Ordinate to adjacent component lead UBF RG16075 - 1100 | P1 | 3.81 | ±0.7 |

| Ordinate to adjacent component lead UBF RG161200 - 1400 | P1 | 7.62 | ±0.7 |

| Lead spacing UBF RG16075 - 1100 | F | 5.08 | +0.75/-0.5 |

| Lead spacing UBF RG161200 - 1400 | F | 10.2 | +0.75/-0.5 |

| Reel width UBF RG16075 - 600 | w2 | 56.0 | Maximum |

| Reel width UBF RG16700 - 1400 | w2 | 63.5 | Maximum |

| Reel diameter | a | 370.0 | Maximum |

| Space between flanges less device | w1 | 4.75 | ±3.25 |

| Arbor hole diameter | c | 26.0 | ±12.0 |

| Core diameter | n | 91.0 | Maximum |

| Box | -- | 64/372/362 | Maximum |

| Consecutive missing places | -- | None | -- |

| Empty places per reel | -- | 0.1% | Maximum |